Volumatic Feeder Machine

Volumatic Feeder Machine

Feed up to 10.9 mt (2 tons) per hour.

- 0.03 m3 (31 ft3) conical polyethylene hopper (food grade material)

- Model 15A w/100 x 500 mm (4 x 20")

- Mild Steel Tray

- 20N Bin Vibrator

- NEMA12 Unicon Control

- Capacity: 1.13 m3/hr (40 ft3/hr) of dry granular material

- Weight: Approximately 34 kg (75 lbs)

Options Available:

- 0.03 m3 (1 ft3) polyethylene extension rings

- Rectangular mild steel or stainless steel hopper

- Stainless steel tray

- Head load deflector

- Dual rate controls and timers

- Covers

Hi-Vi Volumatic Feeder Machines

Eriez Hi-Vi Volumatic Feeder Machines provide dual vibratory action to assure the proper flow of dry bulk material for measured discharge rates.

These one-piece, compact, rugged assemblies are ideal for use in conduction with weigh scales, packaging and bagging equipment, small batch operations, and where additive feeding is being performed either continuously or intermittently.

Each Hi-Vi Volumatic Feeder Machine has been scienti cally designed in size, shape and vibratory action to give you the most ef cient precision feeding possible. Models are available in three popular sizes, with variable feed rates ranging from a few pounds to 15 tons per hour.

Operating Benefits

Positive control of feed, so important to packaging and bagging operations, is assured by the elimination of rear-end dead spots and front-end ip. The rugged hopper with adjustable discharge spout is easily removed from the frame for cleaning. All models

are available for dusty locations—and as specially constructed units for installation in those areas where Class II, Group G equipment is normally used.

Eriez’ standard line of Hi-Vi Feeders and Bin Vibrators with their proven, exclusive construction features and operating advantages are the components used to make these feeder machine assemblies.

All models are furnished with compact, maintenance-free, variable transformer type AC controls. The box can be installed on the frame

of the unit or remotely in any convenient location. The controller can be furnished with a dual control for “fast” and “dribble” feed rates where necessary. Various timers are available for any number of timed or intermittent feeding phases.

The Eriez Hi-Vi drive system, based on a permanent magnet, replaces recti ers by providing an inherent recti cation system. This means more operating forces, no energy lost to the recti er, more ef ciency.

Entirely Enclosed Unit

The Hi-Vi Vibratory Feeders and Bin Vibrators used in these Feeder Machines are entirely enclosed. The feeder is so designed that the drive elements are completely protected against damage or decreased ef ciency due to contamination by moisture and foreign materials.

Uniformity of Feed

The Feeders are designed to produce the most uniform feed possible, consistent with the wide variety of existing eld applications. They provide instant starts and stops with a minimum of product carry-over.

Operation

In operation, the adjustable spout at the bottom of

the hopper can be adjusted as required to obtain the optimum depth of ow. Once this has been established and the adjustable spout secured, the best feed and vibration rates of the feeder and the unit vibrator can be obtained by adjusting the double controller.

Timing and/or dual feeder control functions can be obtained with special controllers designed to provide such functions.

Product Table

| Item Name | Part Number | Description |

|---|---|---|

|

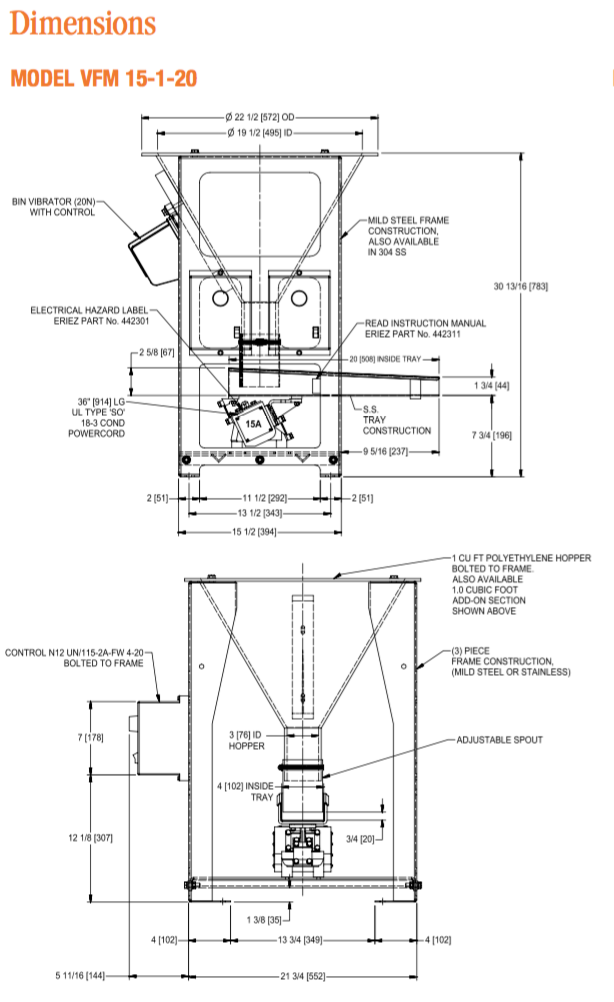

Volumatic Feeder Machine

|

13134202

|

MODEL VFM 15-1-20 - Feeder

|