Magnetic Pulleys

Eriez Magnetic Pulleys

Eriez provides a uniform permanent magnetic pulley that will transform your belt conveyor into a powerful self cleaning magnetic separator. The axial interpole magnetic circuit provides a uniform magnetic field to remove tramp iron from material on almost any belt conveyor.

Eriez Magnetic Pulleys provide ideal automatic removal of unwanted iron from materials conveyed on belts to prevent machinery damage and product contamination for sand, gravel, limestone, recyclables, wood products, food, chemical, mining, rock products, ceramic, paper, plastic, rubber, coal handling and foundry operations.

Features & Benefits:

- Powerful and reliable

- Prevents machinery damage and product contamination

- Automatic separation of heavy tramp iron from conveyor transported materials

Principle of Operation

Eriez Magnetic Pulleys are widely used as head pulleys in belt conveyors for continuous automatic removal of damaging tramp iron from a variety of materials.

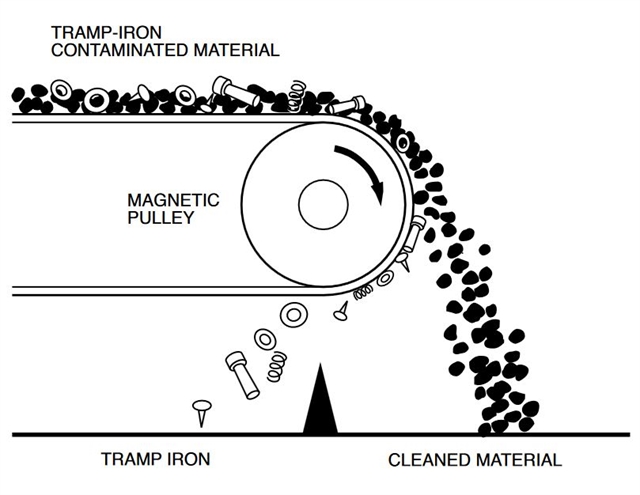

As illustrated in Figure 1, tramp–iron contaminated material comes within the pulley’s magnetic field, the tramp iron is attracted and held to the belt until it reaches the underside, passes out of the magnetic field, and is separately discharged. The cleaned, nonmagnetic material is discharged over the pulley in a normal trajectory.

A stainless steel splitter assembly is required to separate segmented material fractions. An adjustable splitter will permit separation fine tuning and provide optimum separation performance for your application.

Figure 1. Operating Principle of a Magnetic Pulley

Pulley Construction

All Eriez Permanent Magnet Axial Interpole Pulleys are constructed of quality steel center tubes with welded dividers to securely hold magnet stacks. Standard pulley models use powerful ceramic magnets in an axial interpole circuit. Pulleys are all–welded heavy duty construction for use in severe applications involving extra long conveyors, heavy loads or start–stop operations. Pulleys are finish painted and hub bore holes are coated to prevent rust or pitting. Options available in the magnetic pulley line include custom pulley face widths, shafts and lagging.

Model AA Pulleys, with a powerful agitating magnetic field, are constructed with Alnico magnet material for use in high temperature applications above 250°F (121°C).

Downloadable Documents

Downloadable Documents